INDUSTRIAL DRIVE SYSTEM

Customised solutions

We develop and design customised solutions.

Traimec specialises in the ceramics and glass industry with the production of drive systems for roller kilns and dryers.

We also provide an excellent industrial facility maintenance service with partial or total replacement, as well as providing technical support and after-sales assistance.

We also operate in the medical-hospital and general industrial markets through customised mechanical applications.

Technology, quality and reliability have always been the keystones of our achievements.

As industrial drive system professionals, we have developed over the years:

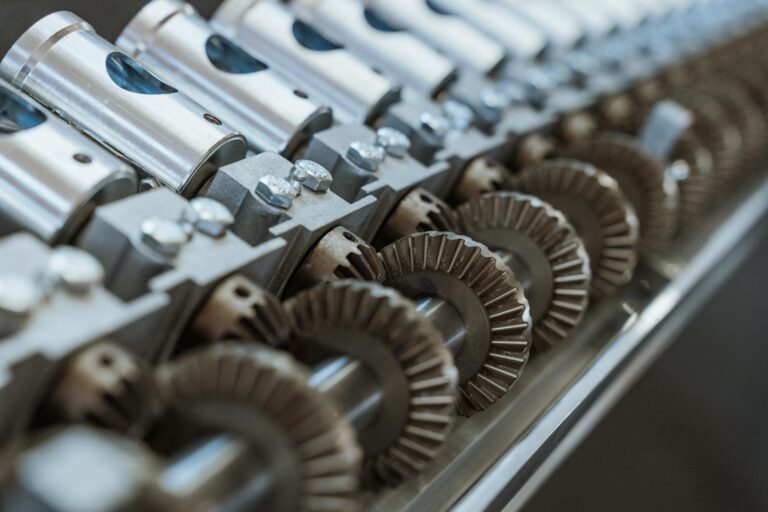

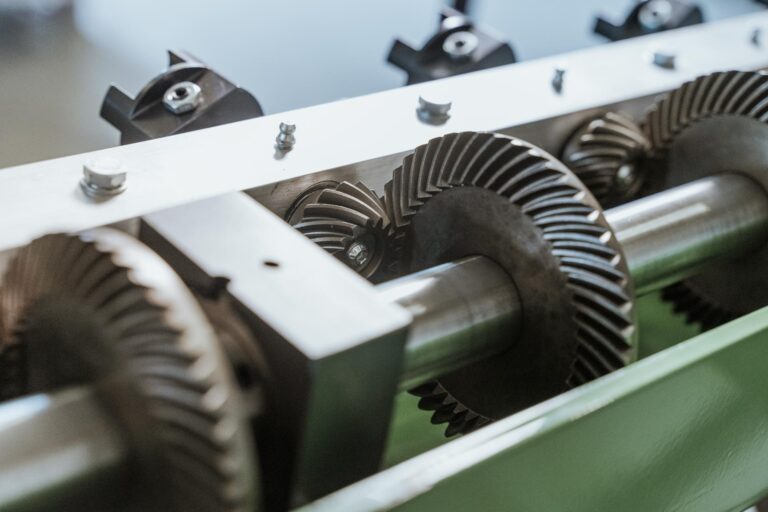

CERAMIC DESIGN

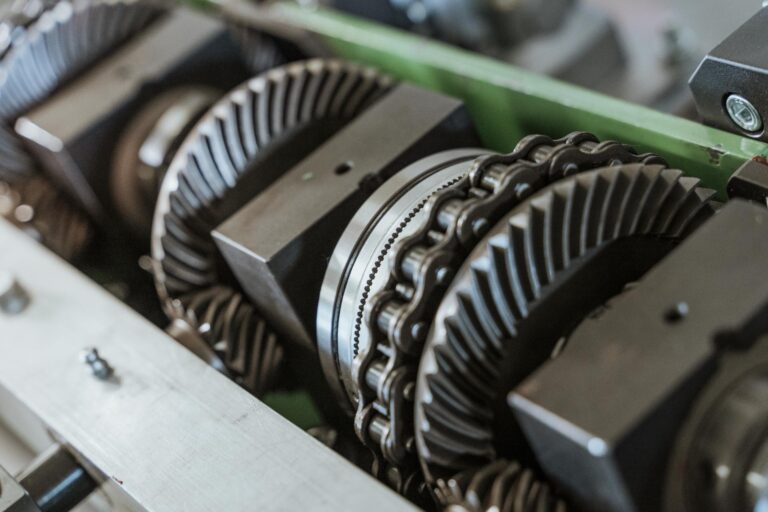

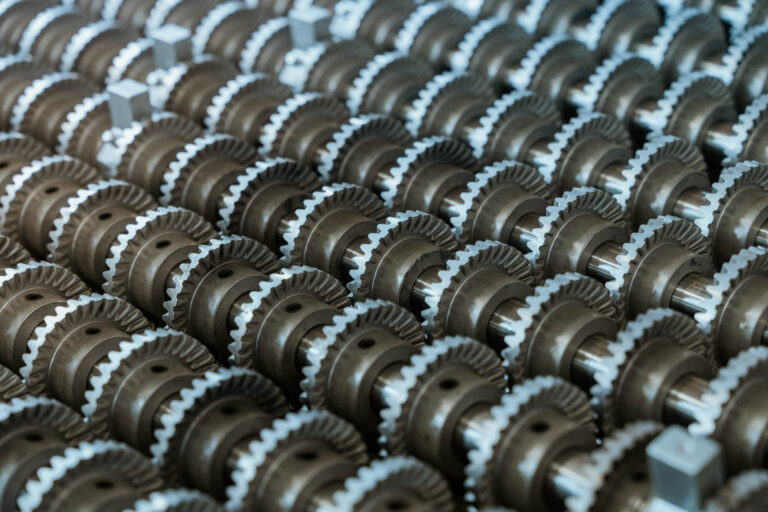

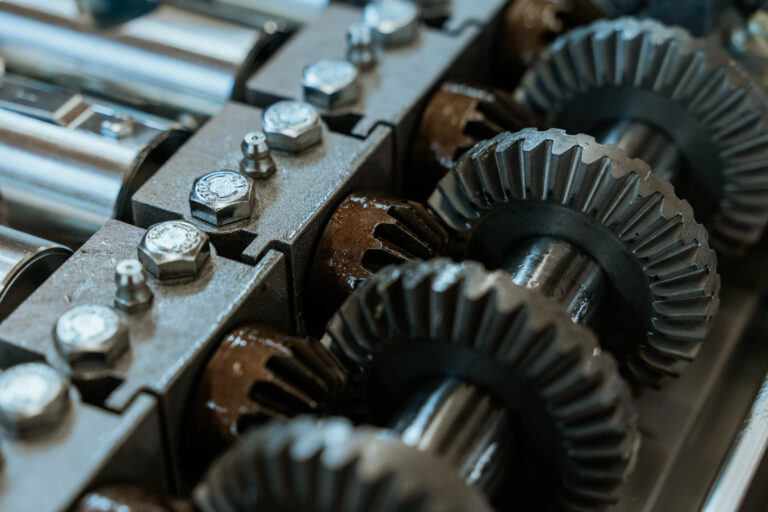

Drive systems for kilns and dryers featuring a bevel gear mechanism with gears in sintered material hardened by heat treatment. Thanks to the self-lubricating properties of sintered materials, the mechanism is suitable for dry running with no oil bath.

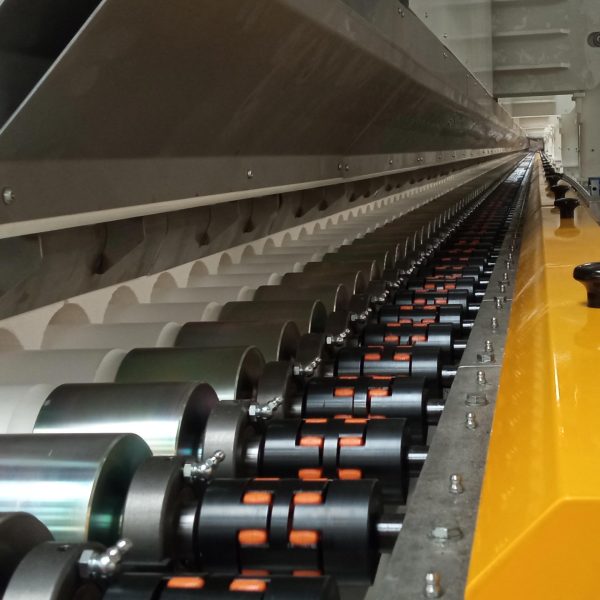

GLASS

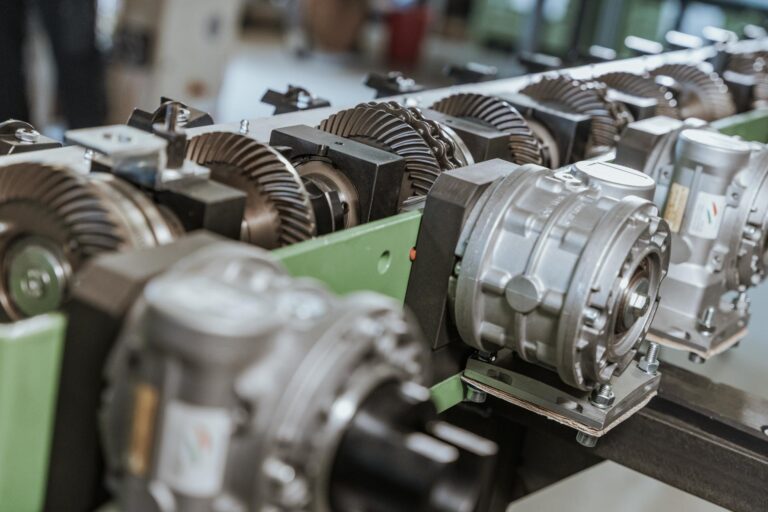

DESIGN

Handling fragile loads requires special technical specifications such as perfect planarity and no backlash. The driveline features Gleason gears and speed-in/speed-up sections assembled on independent segments in a single module.

ROLLER TURNING MACHINE

Designed by Traimec, it was created with the specific purpose of keeping ceramic rollers in rotation as soon after being extracted from the kiln. To preserve the future functionality of the rollers, due to the high temperatures at the moment of extraction, it becomes necessary to maintain them in constant rotation at the same speed as the kiln until complete cooling.

Customer customisations are possible in terms of:

- Number of rollers

- Rollers diameter

- Rollers length

- Rotation speed (No. of revolutions/min)

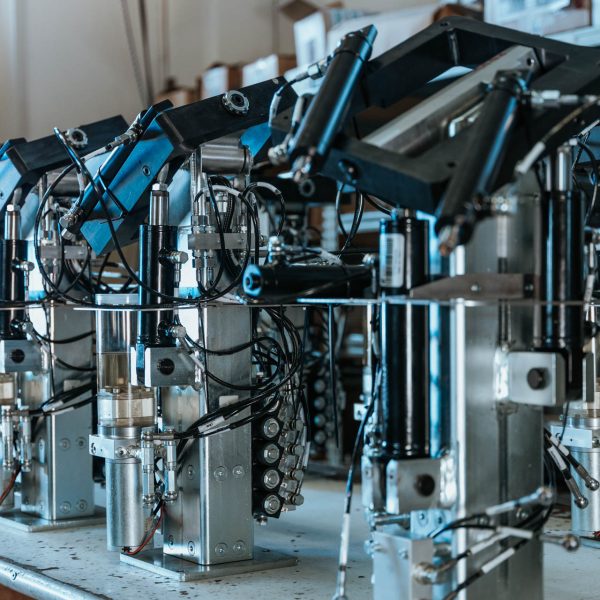

MEDICAL-HOSPITAL DESIGN

Expanding mechanical know-how combined with hydraulics: Traimec's design expertise extends to compactly dimensioned movement systems for operating room equipment. The medical technology area demands a high quality standard, hence strict quality control at every stage of production and meticulous component testing.

Complete solutions for industry

TRAIMEC can satisfy diverse needs by providing different services

Support and consulting

Design

Complete machine development

Preassembled units

Outsourced production of mechanical parts

Drive systems maintenance

Partial or total drive replacement

Proof of perfect symmetry and flatness of our roller handling system.

The test of an unofficial nature was carried out at the end of installation of the kinematics as a demonstration of perfect compliance and conformity of our motorization.